Tel: +86371-68582909

Email: [email protected]

English

Tel: +86371-68582909

Email: [email protected]

English

This special machine is secondary developed on the basis of the five-axis robot CNC system, using laser scanning, embedded batch teaching program, five-axis interpolation linkage, especially suitable for welding bridge steel structures with flaw detection requirements.

This special machine is secondary developed on the basis of the five-axis robot CNC system, using laser scanning, embedded batch teaching program, five-axis interpolation linkage, and can weld wavy workpieces such as containers and corrugated boards.

The forklift mast straightening machine is used to correct the inner and outer masts of forklifts. Its main features are as follows:

The forklift gantry welding robot workstation is used for the welding process of the inner and outer masts of forklifts.

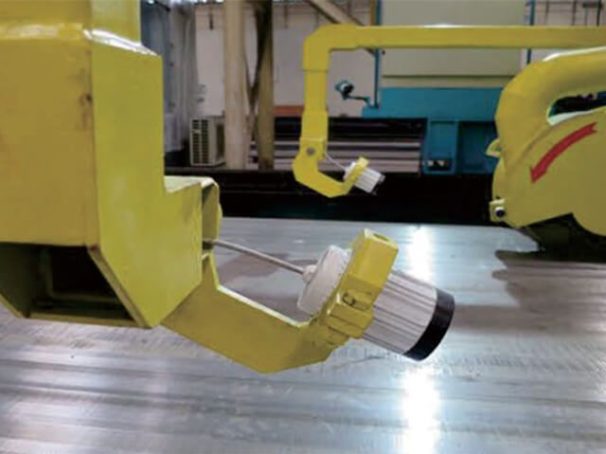

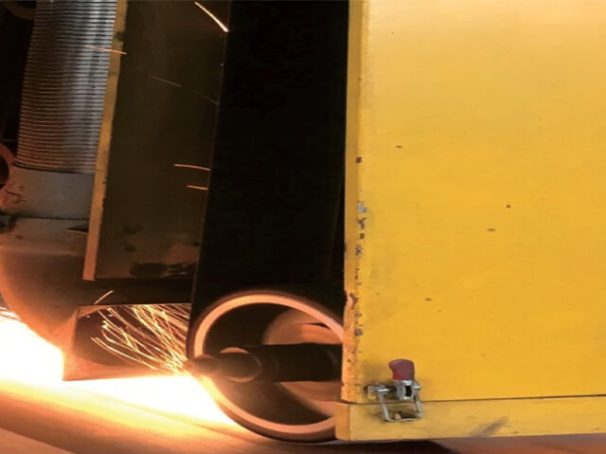

Mainly used to process cracks, pits, pits and other defects on the surface of steel plates, with a processing efficiency of 14~25m²/h.

Mainly used to process cracks, pits, pits and other defects on the surface of steel plates, with a processing efficiency of 14~25m²/h.

One device is equipped with a grinding wheel machine head and a sanding belt machine head or a multi-functional grinding head.

Wet grinding generates less heat, which can effectively reduce thermal deformation of the workpiece and burns on the workpiece surface.

It can grind and polish the inner and outer walls of the pipe. Digital control, input various grinding process parameters in the CNC system to achieve full-automatic grinding of the pipe.

Leave Message