Why Choose Us

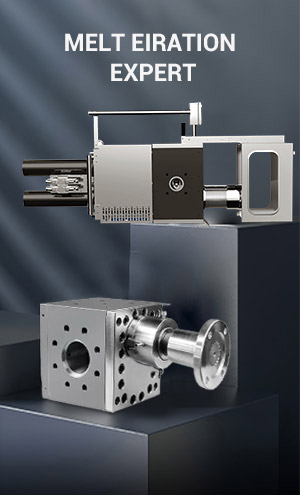

Zhengzhou Batong Intelligent Equipment Technology

Batong Intelligent focused on R&D and manufacturing of melt filtration systems, the company operates a 200-acre factory equipped with over 100 high-precision CNC machining centers and cutting-edge equipment. Through collaborations with universities and research institutions, it has obtained 38 national patents. The company has provided customized production lines and laboratory equipment for global enterprises including Formosa Plastics, Lesso, Borouge, Sabic, and CSSC, driving continuous technological innovation in the industry.