Tel: +86371-68582909

Email: [email protected]

English

Tel: +86371-68582909

Email: [email protected]

English

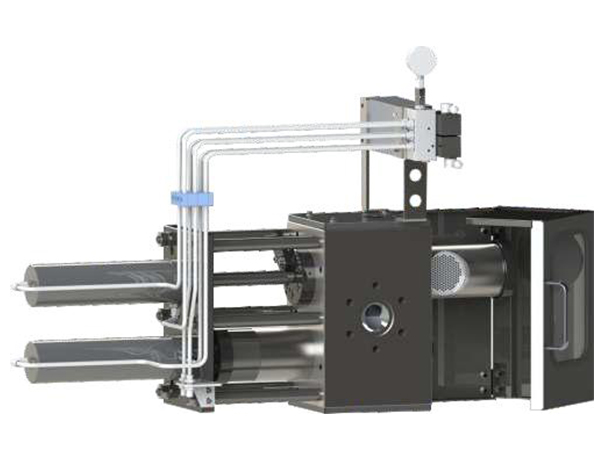

The double-column continuous screen changer is designed with an exhaust system, which can fully remove the gas contained in the material and the porous plate to be replaced, prevent the gas from forming in the product during the screen change process, and improve the quality of the product.

The exhaust system is designed to fully remove the gas contained in the material and the porous plate to be replaced, prevent the gas from forming in the product during the mesh replacement process, and improve the quality of the product.

The exhaust system is designed to fully remove the gas mixed in the material and the porous plate to be replaced, prevent the gas from forming in the product during the mesh replacement process, and improve the quality of the product.

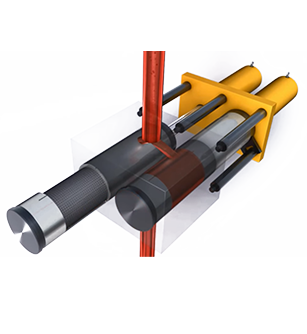

The double-column fully wrapped screen changer is designed with an exhaust system, which can fully remove the gas mixed in the material and the porous plate to be replaced, prevent the gas from forming in the product during the screen-changing process, and improve the quality of the product.

It has good sealing characteristics, rigid sealing and long service life; It is suitable for high-capacity, high-efficiency, high-output continuous operation of large-scale extrusion equipment.

Leave Message