Tel: +86371-68582909

Email: [email protected]

English

Tel: +86371-68582909

Email: [email protected]

English

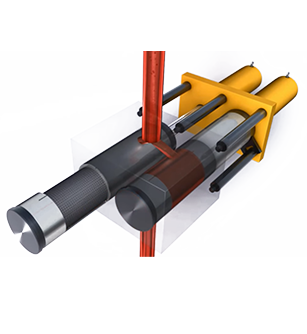

The double-column fully wrapped screen changer is designed with an exhaust system, which can fully remove the gas mixed in the material and the porous plate to be replaced, prevent the gas from forming in the product during the screen-changing process, and improve the quality of the product.

Application

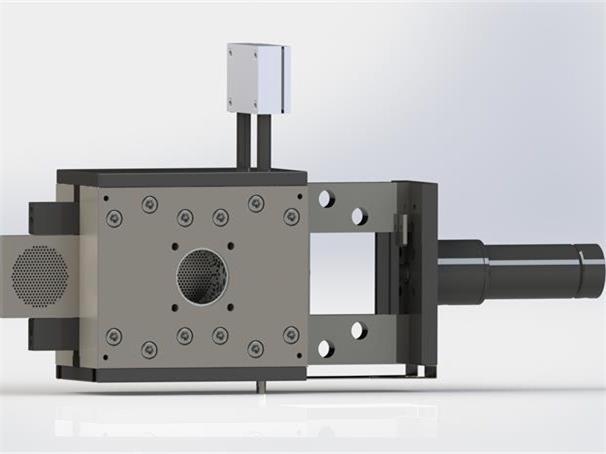

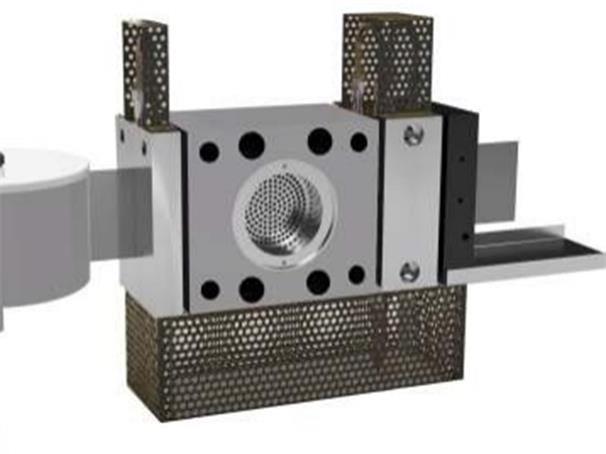

This series of screen changers are designed as single-column or double-column filter cartridge structures with large filtration areas. They can realize two-effect filters working at the same time and can change screens without stopping the machine. They are designed with a material introduction and exhaust system to fully remove gas from the material to ensure product quality. They are designed with a static mixing structure to improve product stability and can realize automatic backwashing function.

| Screen Dimensions | 100mm-250mm |

| Throughput | 200kg/h-5000kg/h |

| Screen Area | 500cm²-4000cm² |

| Heat power | 5Kw-16Kw |

| Operating temperature | ≤350℃ |

| Voltage | 220V/380V |

| Pressure | ≤25Mpa |

Batong Intelligent will provide personalized services based on the different needs of customers, providing customers with a better service experience.

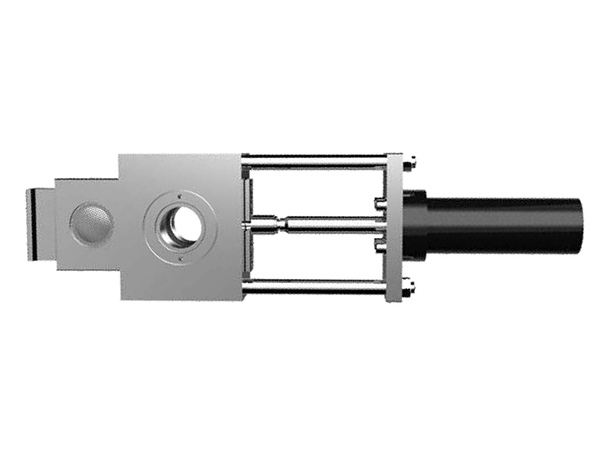

This series of screen changers uses two screens at the same time. When changing the screen, one screen works, and the other is replaced, without interrupting the material flow or stopping the machine from changing the screen.

This series of filters consists of a 10-meter-long filter belt, a screen changer body, a heating/cooling system

Adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated during use.

The hydraulic pump station designed for the screen changer has the characteristics of small size, large thrust, stable operation, simple operation, and convenient maintenance.

Leave Message