Tel: +86371-68582909

Email: [email protected]

English

Tel: +86371-68582909

Email: [email protected]

English

Suitable for inner longitudinal seam submerged arc welding of square or round cylinders such as shipbuilding square tubes, bridge steel structure square tubes, 5G communication towers, power towers, etc.

Suitable for welding heavy H-beam and box beams, multi-layer and multi-pass welding process, welding gun touch positioning function to compensate for workpiece position deviation, equipped with heavy-duty positioner, hydraulically driven automatic positioning fixture clamping, more convenient operation.

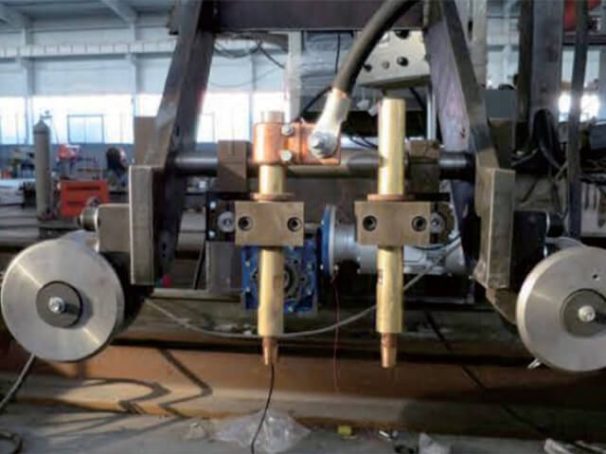

Different arc guides are selected according to different workpiece types, which can adapt to H-beams with larger flange plate depth. It can be welded with a single head or multiple heads at the same time. It can be equipped with submerged arc welding single wire welding or double wire welding.

This special machine is secondary developed on the basis of the five-axis robot CNC system, using laser scanning, embedded batch teaching program, five-axis interpolation linkage, especially suitable for welding bridge steel structures with flaw detection requirements.

This special machine is secondary developed on the basis of the five-axis robot CNC system, using laser scanning, embedded batch teaching program, five-axis interpolation linkage, and can weld wavy workpieces such as containers and corrugated boards.

The forklift gantry welding robot workstation is used for the welding process of the inner and outer masts of forklifts.

Leave Message