Tel: +86-15286835176

Email: [email protected]

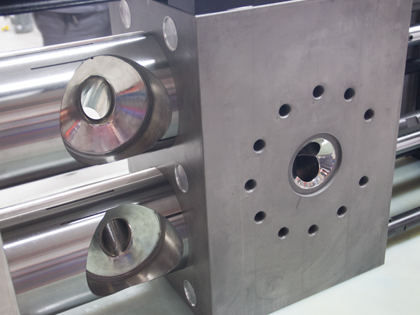

| Model | Screen Size (mm) |

Filtration Area (cm2) |

Production Capacity (Kg/h) |

Heating Power (KW) |

Working Pressure (Mpa) |

| SKB-Z2-120 | φ100 | 157 | 110-350 | 7.2 | ≤25 |

| SKB-Z2-160 | φ135 | 286 | 300-700 | 10.4 | ≤25 |

| SKB-Z2-200 | φ155 | 377 | 400-1000 | 12.9 | ≤25 |

| SKB-Z2-300 | R85-45 | 606 | 500-1500 | 21 | ≤25 |

| SKB-Z2-450 | R90-110 | 904.6 | 550-1800 | 28 | ≤25 |

| SKB-Z2-600 | R115-80 | 1198 | 550-1800 | 31 | ≤25 |