How to choose screen changer for different plastic raw materials

Different processing scenarios have varying requirements for raw material purity, production continuity, and pressure stability. Choosing an inappropriate screen changer often leads to frequent shutdowns, product scrap, or waste.

1.Films (especially food packaging films and optical films) have strict requirements for raw material purity and thickness uniformity. A 0.1mm impurity can cause film breakage, and pressure fluctuations during screen changing can lead to deviations in film thickness.

* Requirements: Filtration precision ≥ 200 mesh, pressure fluctuation during screen changing < 0.5MPa, and support for continuous production.

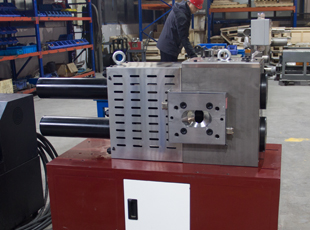

* Recommended selection: The double filter cylinder screen changer is the optimal solution. Its double-cylinder alternating design allows screen changing without interrupting the material flow. When paired with high-precision metal screens (200-400 mesh), it can trap fine impurities. Meanwhile, the double filter cylinder minimizes pressure fluctuations, ensuring stable film thickness.

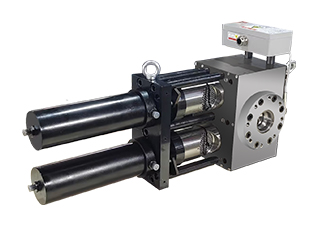

2.In pipe production (e.g., PE water supply pipes, PVC drainage pipes), raw materials are mostly high-viscosity melts, and the extrusion pressure can reach 30-50MPa.

*Requirements: High pressure resistance (≥50MPa), resistance to melt erosion, and filtration precision of 100-150 mesh (to trap coarse impurities like sand and metal debris).

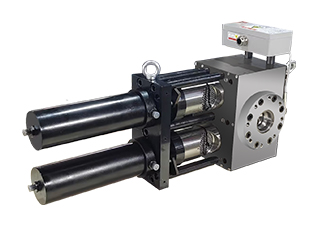

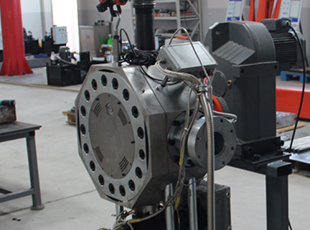

* Recommended selection: Double piston screen changers are the first choice. Their piston-type sealing structure can withstand high-pressure impacts, and the rapid screen switching via the plunger during replacement reduces pipe dimension deviations caused by sudden pressure drops. For large-diameter pipe production lines (capacity > 1000kg/h), a self-cleaning screen changer can be used as pre-filtration to trap large particles first, extending the service life of the piston screen changer's filters.

3.In pelletizing production, raw materials may be mixed with impurities such as catalyst residues and cross-linked particles. Inadequate filtration will directly affect the quality of finish products.

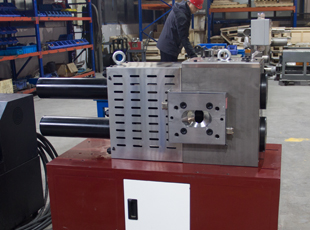

* Requirements: Graded filtration (first removing large impurities, then controlling fine ones), total filtration precision up to 150-300 mesh, and support for high capacity (2000-5000kg/h).

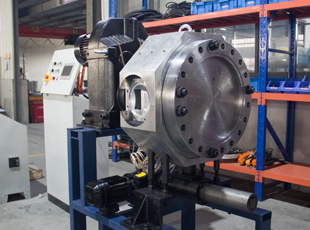

*Recommended selection: The combination of "self-cleaning screen changer + plate screen changer + melt pump". The first stage uses a self-cleaning screen changer (80-120 mesh) to quickly remove large impurities like plastic particles and metal blocks, reducing the burden on subsequent filters. The second stage uses a plate screen changer (200-300 mesh) to trap fine impurities and improve pellet purity. Finally, a melt pump stabilizes the pressure to avoid pressure decay after two-stage filtration, which could affect pellet uniformity.

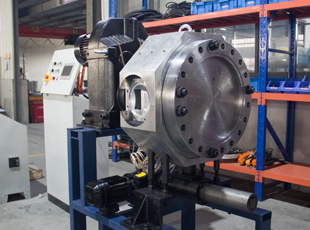

4.Recycled plastics (such as waste films and waste bottle flakes) contain high levels of impurities, which may include soil, fibers, and metal wires. Additionally, the viscosity of raw materials fluctuates greatly, making ordinary screen changers prone to filter clogging and frequent shutdowns.

* Requirements: Strong anti-clogging capability, long screen changing cycle (≥8 hours), and moderate filtration precision 50-100 mesh is sufficient.

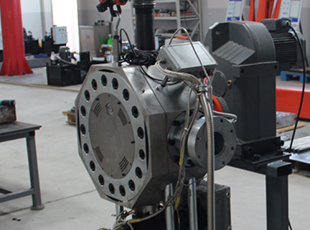

* Recommended selection: Self-cleaning screen changers are the mainstay of recycling lines. Their rotating scrapers can automatically remove impurity buildup on the screen surface, eliminating the need for frequent manual screen replacement – ideal for recycled materials with impurity content > 5%. If the recycled material is to be used in scenarios with higher purity requirements (such as injection molding), a piston tyoe screen changer can be added for secondary filtration, increasing the precision to above 150 mesh.