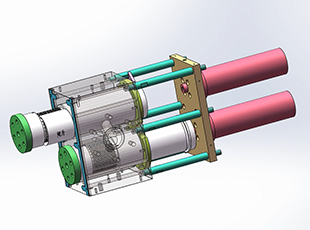

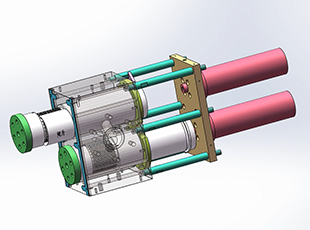

Working principle of double filter cylinder screen changer

The double filter cylinder screen changer comprises a main body, two pistons (each with 1-2 filter cylinder-type screens), a hydraulic station, and other components, forming a complete filtration system. The two pistons operate simultaneously: when one is driven by a hydraulic or mechanical device for screen replacement, the other remains in melt flow. Furthermore, its unique material introduction and exhaust design ensures that screen changes can be performed without stopping the extruder or interrupting the melt flow.

The double filter cylinder screen changer has a filtration area of up to 4,000 square centimeters and a filtration capacity of up to 3,500 kg/h. Its filtration precision can be adjusted by changing the mesh number of the metal screen according to requirements, enabling high-precision filtration. With large output, high filtration precision, and almost no pressure fluctuation during the screen changing process, the double filter cylinder screen changer is suitable for the filtration production of most polymers and is the preferred choice in the plastic processing industry.