On May 18, 2025, at the Shanghai New International Expo Center, the 36th International Plastics and Rubber Exhibition was in full swing. In the "China Plastics and Rubber Equipment Area" of W5 Hall, the booths of enterprises such as Zhengzhou Haikoo and Bate were surrounded by visitors from all over the world - their gazes were all fixed on several "net changing devices that can keep the production line running without stopping".

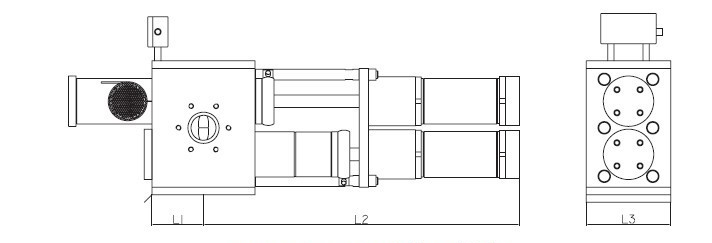

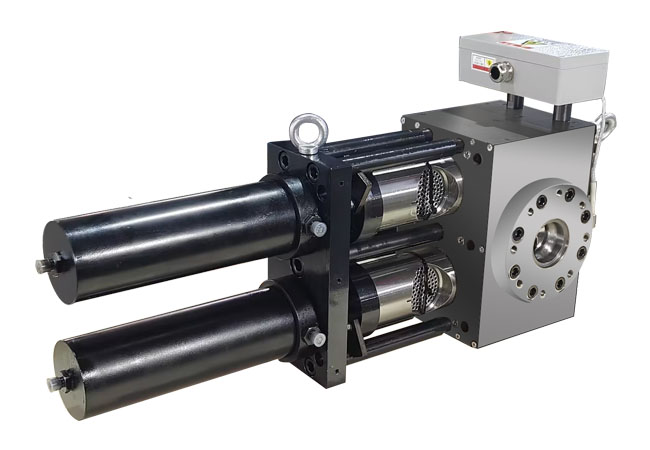

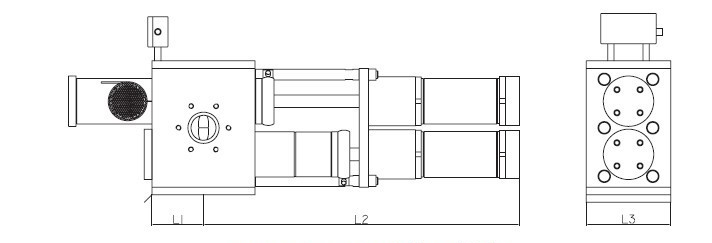

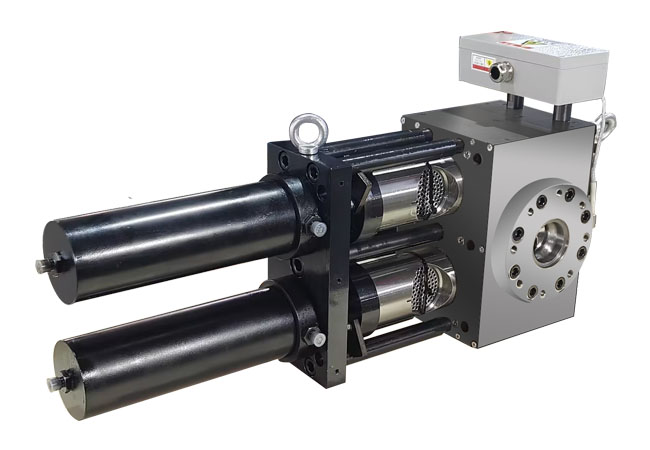

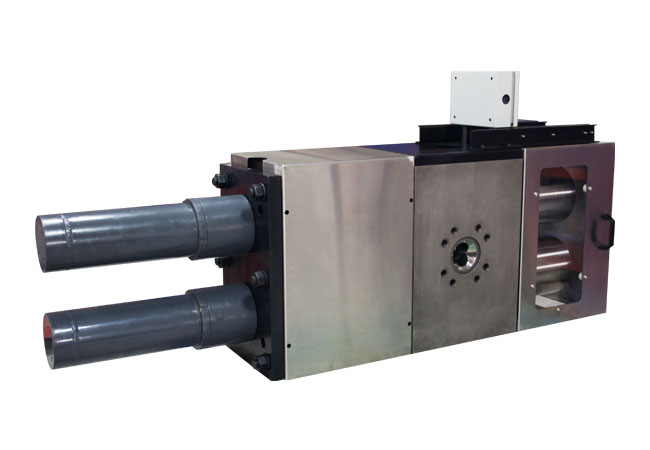

"Look, during the net replacement process, the material flow hardly fluctuated at all!" German customer Müller leaned against the glass cover of the Heiko mesh belt-type fully automatic net replacement machine and was filming while exclaiming in amazement. This net replacement machine adopts a customized mesh belt design, with the filter net length reaching up to 5 meters, and it can support continuous filtration for 72 hours. When the melt pressure reaches the set value, the control system will automatically start the heating and mesh movement process, with the mesh moving speed precisely to the "millimeter level", completely solving the pain point of traditional net replacement machines where "stoppage always leads to loss of efficiency". The adjacent double-column non-stop net replacement machine even more impressed the Southeast Asian customers: The double-column structure can cope with high-viscosity melt production environments, and even in the PP granulation line, it can maintain the continuous operation of the production line. "Our factory needs to operate without interruption for 24 hours, and this product exactly solves our 'big headache'!" A Thai exhibitor asked for the price on the spot.

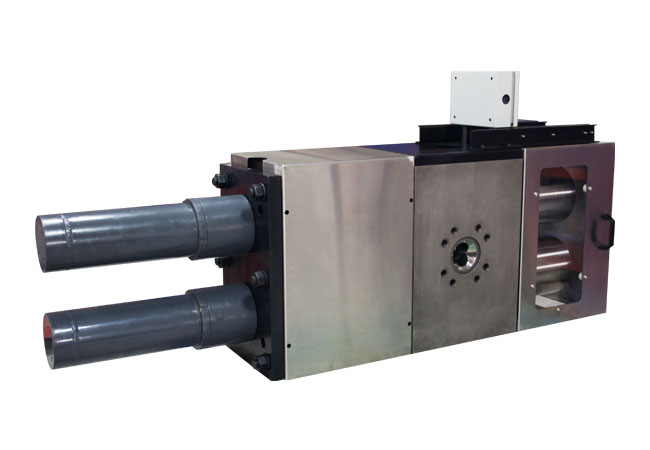

Not far away, at the booth of Zhengzhou Bate, it was equally bustling. At the hydraulic mesh replacement device of theirs, the purchasing representatives from the Middle East were carefully flipping through the product manual. This mesh replacement device not only enables "mesh replacement without stopping production", but also can automatically detect the impurity content based on the melt pressure and automatically adapt to high-precision filters above 200 mesh - this means that when producing high-transparent food-grade films, the impurity filtration accuracy can be improved to "micron level" 78. "Our production line previously used mesh replacement devices from Europe. Each time the filter was replaced, it required a 1.5-hour stoppage, and each time we lost over 10,000 yuan. The automated design of this hydraulic mesh replacement device is truly an 'industrial wonder'!" said the purchasing representative.

From "solving the pain points of network replacement downtime" to "achieving automated and precise filtering", the breakthrough in China's network replacement equipment technology is essentially an innovation centered on user needs. At this exhibition, enterprises such as Haikang and Baotai received over 120 groups of overseas customers. More than 20 enterprises reached agreement on cooperation, covering regions such as Europe, Southeast Asia, and the Middle East.

"Previously, we purchased European meshing devices. Now, the products from China have more advanced technology and are more cost-effective." Miller's words might just be the best illustration of how Chinese meshing devices are "going global". When "不停机换网" and "automated filtration" became the "labels" of Chinese meshing devices, this "amazing debut" at the international exhibition not only enabled Chinese brands to firmly occupy the "C position" in the global rubber and plastic equipment market, but also allowed the world to see - Chinese technology is using innovative solutions to real problems to rewrite industry rules.