The

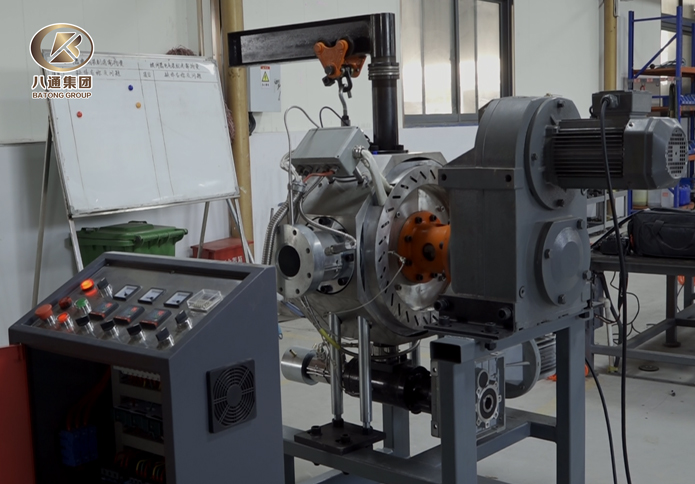

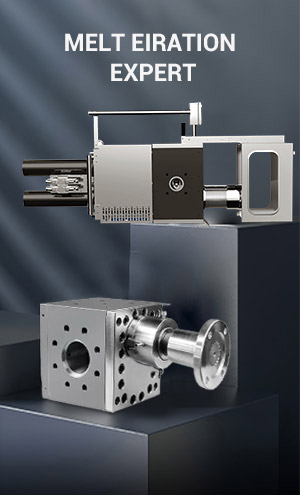

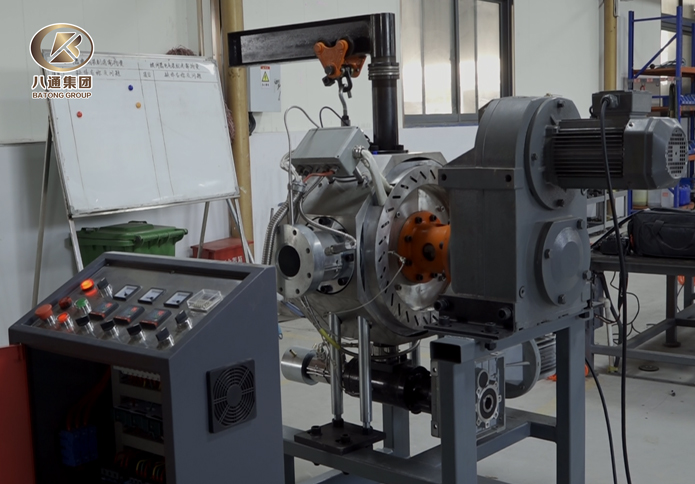

Self-Cleaning Screen Changer from Zhengzhou Batong Intelligent is a new filtration system. It is made for the smart factories of the future. It completely abandons the physical operation mode of traditional screen changers that require shutdown, disassembly, and screen replacement. It uses a built-in, fully automatic cleaning system. This system removes dirt from the filter screen while the production line keeps running. This is a big step from "periodic replacement" to "continuous self-cleaning." It is the best choice for no downtime, no consumables, and full automation in continuous production.

Core Working Principle

Core Working Principle: Online Regeneration, Perpetual Filtration

The heart of the system lies in its innovative self-cleaning actuator. When contaminant buildup on the main screen causes a pressure increase, the system does not switch positions or stop. Instead, it automatically initiates a cleaning cycle. Through precise mechanical scraping, high-pressure backflushing, or special screen belt movement (depending on the model), the impurities adhering to the screen surface are instantly stripped away and expelled from the system. The entire process is completed automatically within seconds, with absolutely no interruption or fluctuation in melt flow, system pressure, or temperature. Filtration performance is restored in real-time.

Disruptive Advantages & Core Value

- True Zero-Downtime Production: Eliminates all planned and unplanned downtime associated with screen changes, pushing equipment utilization and capacity to the theoretical maximum.

- Ultimate Operational Cost Savings: Completely eliminates labor costs for screen changes and the expense of costly screen pack consumables, achieving long-term cost optimization.

- Unmanned Intelligent Operation: The entire process is automatically monitored and controlled by a PLC system, triggered by differential pressure or timer settings, requiring no manual intervention. It is a key component of the "lights-out factory."

- Unparalleled Process Stability: Absolutely no sudden changes in pressure, temperature, or flow rate due to screen changes during production, providing an excellent stability foundation for manufacturing high-end, high-value-added products.

- Environmental & High Efficiency: Reduces filter screen waste generation; continuous cleaning capability ensures the melt remains at a high level of purity, directly enhancing product quality.

Application Fields

Application Fields

- This equipment is the perfect answer for the following challenging, high-demand continuous production scenarios:

- Plastic Recycling & Repelletizing: Efficiently processes post-consumer recyclate with high and complex contamination levels, ensuring continuous operation.

- High-End Film & Sheet: Production lines for BOPP, optical films, and specialty sheets with stringent requirements for purity and process stability.

- Pipe & Profile Extrusion: Ensures flawless inner/outer walls of large-diameter pipes and precision profiles.

- Long Fiber Reinforced & Highly Filled Compounds: Handles challenging materials prone to screen clogging, maintaining smooth production line operation.

- 24/7 Non-Stop Production Lines: Provides fundamental security for factories requiring year-round, uninterrupted operation.

Choosing the

Self-Cleaning Screen Changer is not just purchasing a piece of equipment; it is integrating a "perpetual motion" filtration ecosystem into your production line. With cutting-edge innovation from Zhengzhou Batong Intelligent, we empower you to achieve a comprehensive leap in efficiency, cost, and quality, securing a competitive advantage in the future of manufacturing.