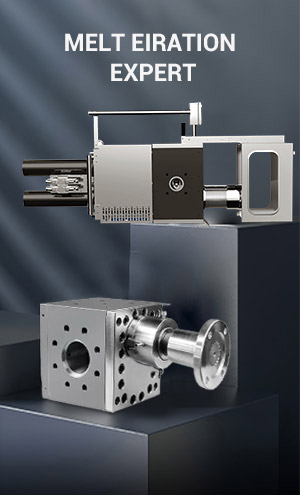

The Manual Screen Changer (typically a manual slide plate type) is an entry-level melt filtration device developed by Zhengzhou Batong Intelligent for users who prioritize ultimate cost-effectiveness and operational reliability. It eliminates complex hydraulic or electric systems, employing a pure mechanical slide plate structure where screen changes are achieved via manual operation of a lever or bolt mechanism. It is known for being cheap to buy and maintain. It has a strong build and requires almost no maintenance. This makes it a great choice for small to medium production lines, batch processing, R&D trials, and budget-friendly projects.

Core Structure & Working Principle

The heart of the device is a precision-machined, high-strength slide plate. The plate is often designed with multiple stations, allowing several screen packs to be pre-installed simultaneously. When the active screen becomes clogged with contaminants, causing an increase in extruder backpressure, the operator manually activates the drive handle or bolts on the side of the unit to slide the plate out. The clogged screen is thus removed from the high-temperature, high-pressure melt stream, allowing for safe cleaning or replacement. Simultaneously, another pre-installed clean screen pack on the slide plate is pushed into the working position. The entire operation is direct and intuitive, requiring no external power source.

Key Advantages & Value

Minimal Capital Investment: Simple structure with no complex hydraulic power units or control systems results in a significantly lower total cost of ownership compared to automatic changers.

Robust & Highly Reliable: All-mechanical design lacks delicate electrical or hydraulic components, offering exceptional stability and long service life in harsh high-temperature, high-pressure environments.

Easy Operation & Maintenance: No need for specialized electricians or hydraulic technicians; regular operators can master screen changes after brief training. Requires minimal daily maintenance.

High Flexibility: Perfectly suited for scenarios requiring frequent screen changes or variable processes, such as raw material trials, color compounding, and small-batch, multi-variety production.

Saves Space & Energy: Compact footprint and no electrical power consumption for operation make it ideal for space-constrained or energy-conscious settings.

Typical Application Fields

The Manual Screen Changer is a cost-effective choice for:

Small Plastic Pelletizing Lines: For filtering recyclates or color masterbatch.

Laboratory & R&D Extruders: Used in new material formulation development, process testing, and small-batch sample preparation.

Auxiliary Profile and Pipe Extrusion Lines: Serving as a backup or primary filter for production stages with less stringent continuity requirements.

Cable Sheathing Extrusion: Suitable for small to medium-sized cable production.

Start-ups or Budget-Conscious Manufacturers: Achieving basic melt filtration at the lowest cost to effectively improve product quality.

Zhengzhou Batong Intelligent's Manual Screen Changer adheres to the design philosophy that "simplicity equals reliability." Manufactured from premium alloy steel, it ensures smooth sliding and dependable sealing. Choosing it means opting for a economical, pragmatic, and uncompromising foundation for production quality.