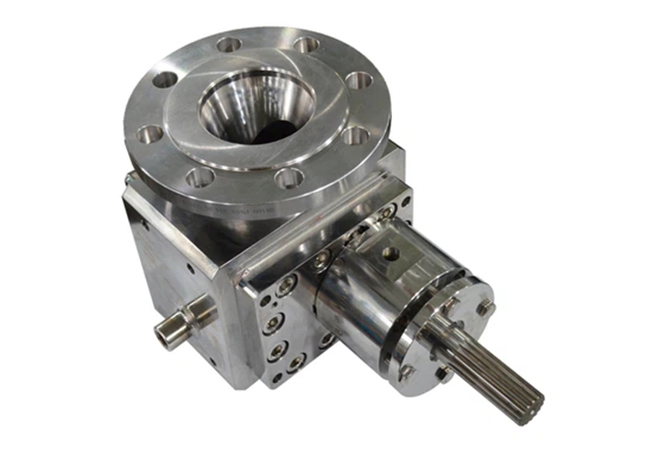

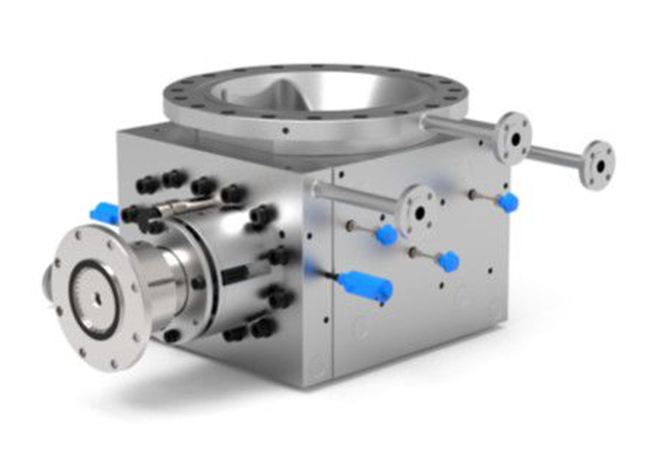

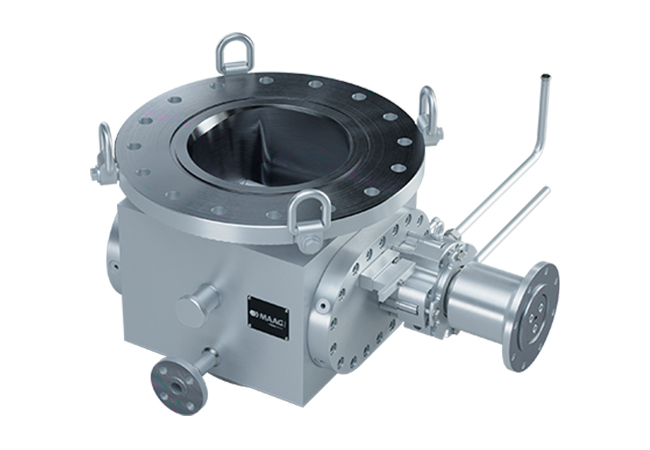

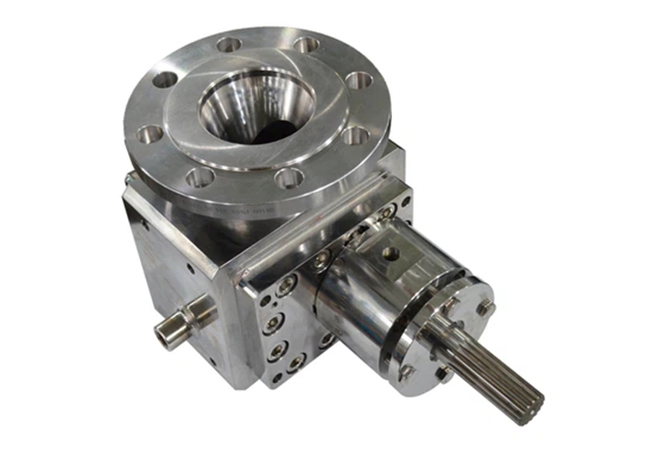

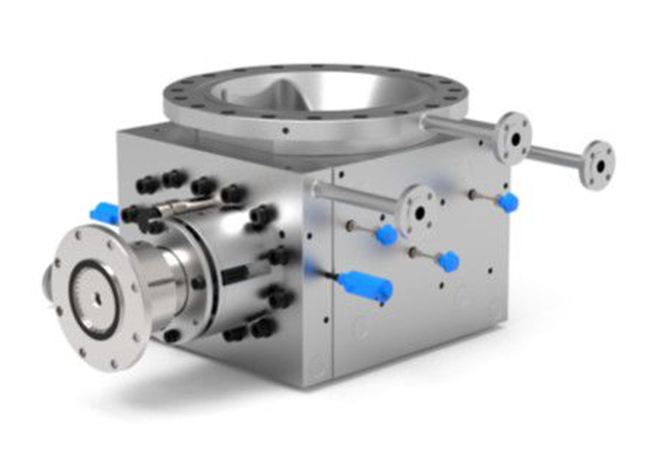

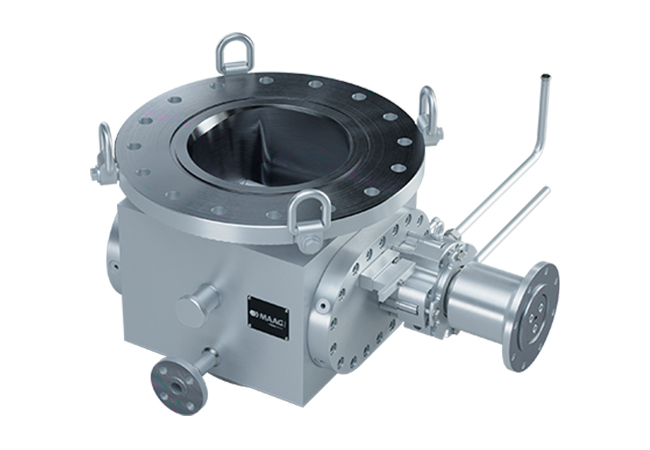

On May 28, 2025, at the Düsseldorf Plastic Machinery Exhibition in Germany, a certain enterprise from Suzhou showcased a high-precision melt pump, which attracted the attention of European buyers. This equipment can control the melt flow rate with an accuracy of ±0.2%, and has been successfully applied to the optical-grade PET film production line, filling the technological gap in the European market.

"The uniformity of film thickness is a core indicator for high-end optical films. Our pump, through the optimization of gear meshing and servo control technology, has reduced the fluctuation amplitude to one-third of that of traditional equipment." The enterprise's R&D director demonstrated the operation data of the equipment on-site. The actual measurement showed that when this pump was transporting high-viscosity melts, the stability of the outlet pressure reached 0.3%, and the thickness deviation of the produced films did not exceed 0.5 micrometers.

Many European film manufacturers placed orders on the spot. The technical director of a German enterprise commented: "In the past, we relied on Japanese equipment. Now, the precision and stability of Chinese products fully meet our requirements, and the price is 40% lower."

During the exhibition, domestic high-precision melt pumps received over 5 million euros of orders from European customers, covering areas such as photovoltaic backsheet films and liquid crystal display substrates. As "Chinese precision" gains recognition in the global high-end manufacturing sector, domestic melt pumps are moving from "following the technology" to "setting the standards".