On May 22, 2025, at the Guangzhou International Rubber and Plastic Industry Exhibition site, a smart mesh replacement device showcased by a certain mechanical company from Zhengzhou sparked a rush to purchase - on the first day of the exhibition, it received orders worth over 15 million yuan from the Middle East and Southeast Asia. Its core technical indicators surpassed those of similar products from Europe and the United States, marking that the domestic mesh replacement device has officially entered the top echelon of the global market.

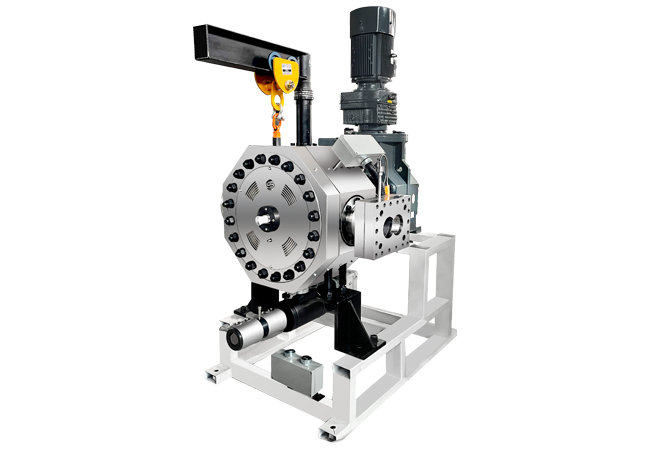

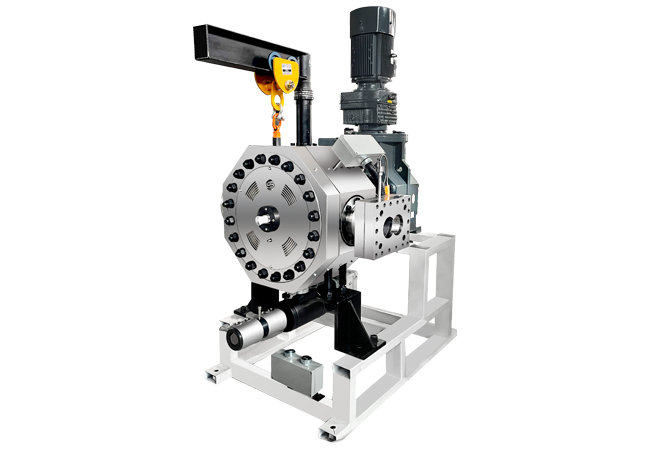

"When the traditional screen changer performs the screen replacement, the pressure fluctuation exceeds 15%, resulting in 'melting marks' on the product. Our intelligent screen changer, through pressure closed-loop control, keeps the fluctuation within 3%." The company's technical director pointed to the running equipment on the exhibition stand and explained. This equipment is equipped with the independently developed "double-column synchronous screen replacement technology", reducing the screen replacement time from the industry average of 30 seconds to 8 seconds, and the melt temperature fluctuation does not exceed 2℃, completely solving the "breakdown" problem in the production of high-value-added products.

What further delighted overseas customers was its "dumb-bell" operation method. The equipment is equipped with an AI algorithm that can automatically adjust the frequency of changing the screen based on the melt viscosity and temperature. The operator only needs to set the target parameters, and the system can run independently throughout the process. "Our factory has a high staff turnover rate. The 'one-click screen change' function of this equipment is extremely practical!" A purchasing director from an Indonesian plastic factory placed an order for 50 units on the spot.

According to the statistics of the exhibition organizing committee, the consultation volume at the booths of domestic mesh replacement equipment manufacturers at this rubber and plastic exhibition has increased by 200% compared to the previous year. Among them, 70% were overseas customers. Industry experts pointed out that domestic mesh replacement equipment has shifted from "replacing imports" to "technology output", and its high cost-effectiveness advantage is driving the global rubber and plastic equipment industry chain to migrate to China.

"Previously, customers always asked 'How long will it last?'. Now they ask 'Can it be customized?'" The sales director of a certain enterprise's words reflect the transformation of Chinese manufacturing from "following" to "leading". When "intelligent network replacement" becomes the new label for Chinese equipment, the "order storm" at this exhibition is writing new notes for the global rubber and plastic industry.