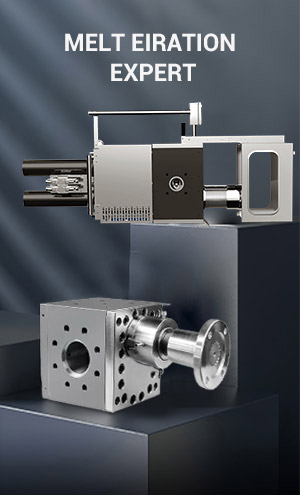

The Double Plate Screen Changer is also know as the Dual-Station Hydraulic Screen Changer, represents an upgraded filtration solution for mid-to-high-end extrusion lines. Building upon the proven slide plate concept, it incorporates a reliable dual-plate (dual-station) design and an integrated hydraulic drive system. This evolution delivers significant performance enhancements in operational automation, faster screen changeover, and minimal pressure fluctuation. It is the ideal choice for production sectors demanding higher efficiency and consistent product quality, such as sheet, film, pipe, pelletizing, and optical fiber cable compound extrusion.

Core Structure & Working Principle

At the heart of the unit are two independent, high-strength pressure plates, each capable of holding a customized multi-layer screen pack. The dual-plate design creates an intelligent “one-in-use, one-on-standby” configuration: one plate is actively filtering within the melt stream, while the other stands ready in the pre-load position with a clean screen pack installed. When the active screen becomes clogged and causes a pressure increase, the hydraulic system activates automatically. It smoothly retracts the clogged plate and simultaneously pushes the clean standby plate into the working position. This entire process is completed automatically within 1-2 seconds. The melt flow path transition is seamless, imposing minimal disturbance on extrusion pressure and temperature, thereby ensuring continuous production and product uniformity.

Key Advantages

Dual-Station Design for Non-Stop Production: The “active/standby” mode enables genuine continuous operation, dramatically improving equipment utilization and output.

Hydraulic Drive for Fast & Smooth Changeover: Automated operation saves time and labor. The switching action is quick and steady, significantly reducing process disruption compared to manual methods.

Minimal Melt Pressure Fluctuation: Precision-engineered flow channels and rapid switching ensure very small amplitude and fast recovery of backpressure spikes, making it ideal for pressure-sensitive, high-precision extrusion.

High Sealing Integrity & Durability: Constructed with premium alloy steels and special sealing materials to withstand high pressure and temperature, ensuring long-term, leak-free operation.

Broad & Flexible Application: Highly suitable for demanding filtration of various plastics (PP, PE, PET, PA) and challenging materials like highly-filled compounds or recyclates.