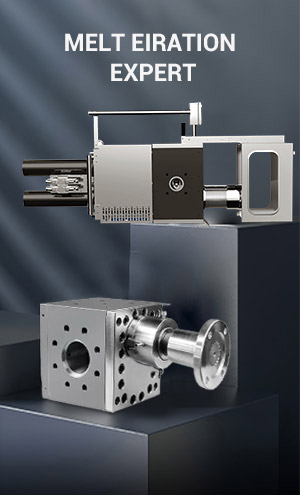

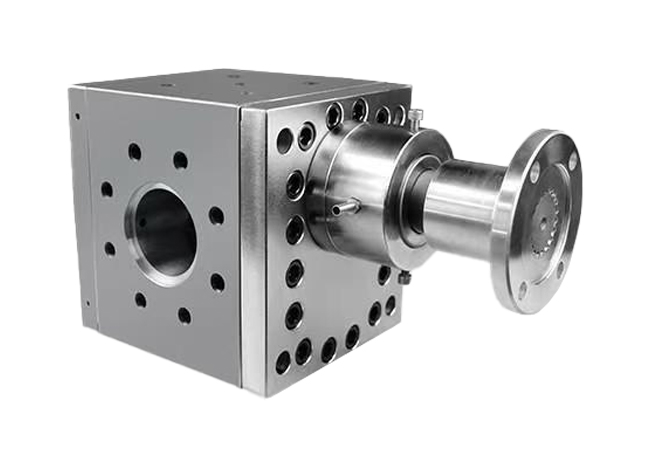

On May 25, 2025, at the International Petrochemical Equipment Exhibition held in Dubai, a high-temperature-resistant melt pump launched by a certain mechanical company in Nanjing became the focus of attention. This equipment can operate stably at a temperature of 500℃, with pressure fluctuations controlled within ±0.5%. It successfully signed a large petrochemical project in the Middle East, with an order amount exceeding 8 million US dollars.

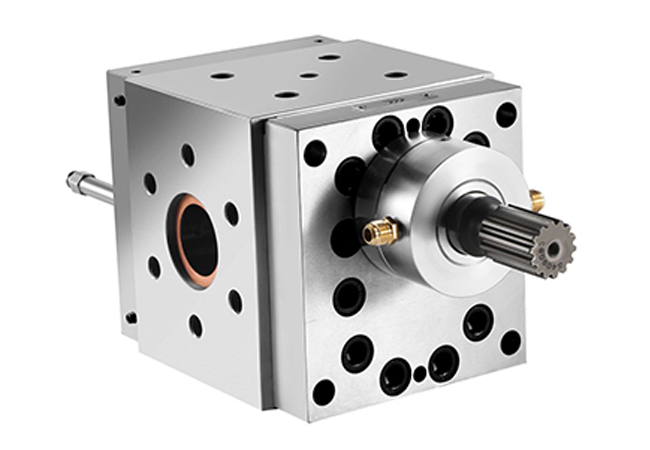

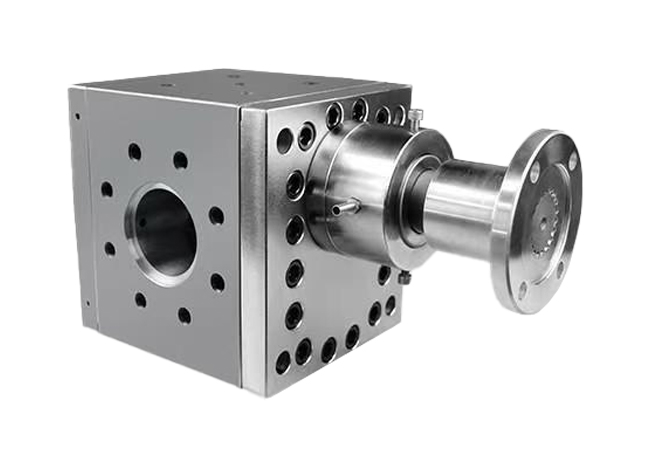

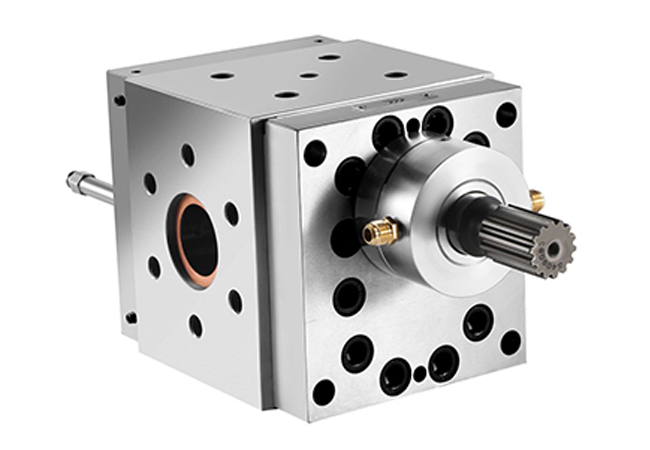

"Traditional melt pumps are prone to seal leakage under high-temperature conditions. Our product adopts a two-stage dynamic sealing technology, combined with special alloy pump bodies, and its service life is 30% higher than that of imported equipment." The company's chief engineer pointed to the simulation device on the exhibition stand and explained. Test data shows that when this pump is used to transport polyphenylene sulfide (PPS) melt, its energy consumption is 18% lower than that of similar products, and it can operate continuously for 24 hours.

Middle Eastern customers are particularly satisfied with the "smart warning" function of the equipment. The system is equipped with built-in sensors that can monitor temperature and pressure parameters in real time. When an anomaly is detected, it automatically triggers an alarm and adjusts the operating status. "The downtime cost of our production line exceeds $100,000 per hour. The stability of this pump gives us great peace of mind," said the project manager.

According to the exhibition statistics, the booth of domestic melt pumps received over 200 groups of overseas customers. Among them, the demand for high-temperature working conditions accounted for 65%. Industry experts pointed out that as the global petrochemical industry upgrades towards higher temperatures and pressures, domestic melt pumps are seizing the international high-end market by virtue of their "high-temperature resistance and low energy consumption" advantages.