The

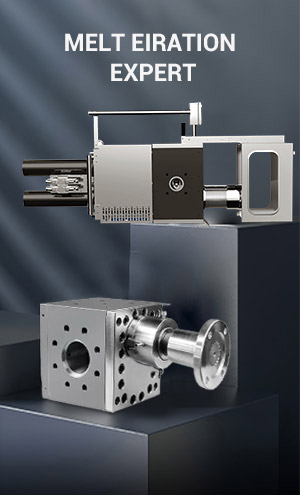

Screen Changer, also known as the

Melt Filter, is an indispensable key component in polymer extrusion lines for plastics, rubber, and chemical fibers. Its core function is to efficiently filter out impurities, gels, and unplasticized particles from the polymer melt without interrupting the production process. This ensures high quality, high purity of the final product, and guarantees continuous, stable operation of the production line.

During extrusion, the polymer melt carries various impurities originating from the raw materials or the production process. If these contaminants enter the die, they can cause defects such as die lines, gels, holes in the product, and even damage expensive dies. The

screen changer intercepts these impurities using a pack of high-precision filter screens. When the screens get clogged, the melt pressure rises to a set value. The device, powered by hydraulic or mechanical force, quickly moves the clogged screen pack out of the melt stream. At the same time, it switches a clean screen pack into the working position. This entire process is completed almost instantaneously, with minimal impact on extrusion pressure, temperature, and output, enabling genuine non-stop continuous production.