The

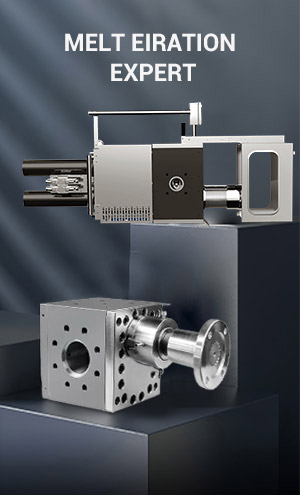

Double Filter Cylinder Screen Changer, engineered by

Zhengzhou Batong Intelligent, is a premium filtration solution engineered for high-output and stringent extrusion applications. This device has a special design with two cylinders and two flow channels. Its main benefits are a large filtration area and continuous operation without interruptions. It is the best choice for sheet, plate, pelletizing, and recycling lines. These lines handle high-contaminant materials, like recyclates. They also aim for high production efficiency and consistent products.

Key Advantages & Value

Key Advantages & Value

- Double Filtration, Doubled Efficiency: Simultaneous operation via dual cylinders and flow paths provides a super-large filtration area in a single unit. This significantly reduces contaminant load per unit area and extends intervals between screen changes, making it particularly suitable for high-output lines or production using recycled materials.

- 100% Continuous Production: The innovative switching mechanism ensures the entire process—from filtration and screen changing to re-engagement—requires no speed reduction or shutdown. This maximizes equipment utilization and output, meeting the needs of modern continuous operation plants.

- Superior Process Stability: Precision-engineered flow channels and venting structures ensure smooth melt pressure transition during screen change and effectively remove gases from the material. This fundamentally guarantees consistent product thickness, appearance, and high quality.

- Robust Durability & High Adaptability: The main body is constructed from high-strength alloy steel with special treatment. The rigid sealing structure guarantees leak-free performance, capable of withstanding high-temperature and high-pressure melt over long periods. It is widely suitable for filtering various thermoplastics and sols like PP, PE, PS, ABS, and PET.

- Intelligent Control: Can be equipped with a fully automatic PLC control system for differential pressure alarm, automatic switching, and process monitoring, reducing manual intervention and enhancing system safety and operability.

Technical Overview

- Filtration Capacity: Capable of meeting medium to high-output production line requirements, depending on the model.

- Working Pressure: Maximum design pressure up to 50 MPa, suitable for high-pressure extrusion processes.

- Working Temperature: Withstands up to 350°C, covering the processing temperatures of polymers.

- Screen Structure: Utilizes specialized rigid screen packs and support frames for sturdiness, durability, and reusability, reducing consumable costs.

Typical Applications

This equipment is a cornerstone for demanding, continuous production, especially ideal for:

- High-End Sheet & Plate: Optical-grade and engineering plastic thick sheets/plates (e.g., PS, ABS, PC, PMMA).

- High-Capacity Pelletizing Lines: Virgin materials, modified engineering plastics, and plastic recycling & re-pelletizing involving complex contaminants.

- Film & Fiber: BOPP, CPP film production lines, spinning, and non-woven fabric lines.

- Pipe & Profile: Large-diameter pipes and profiles with stringent requirements for inner/outer wall smoothness.

Choosing the Double Filter Cylinder Screen Changer equips your production line with the dual assurance of "large-capacity filtration" and "non-stop operation". With precision engineering and reliable design from Zhengzhou Batong Intelligent, we empower you to achieve stable, efficient, and high-quality polymer processing production.