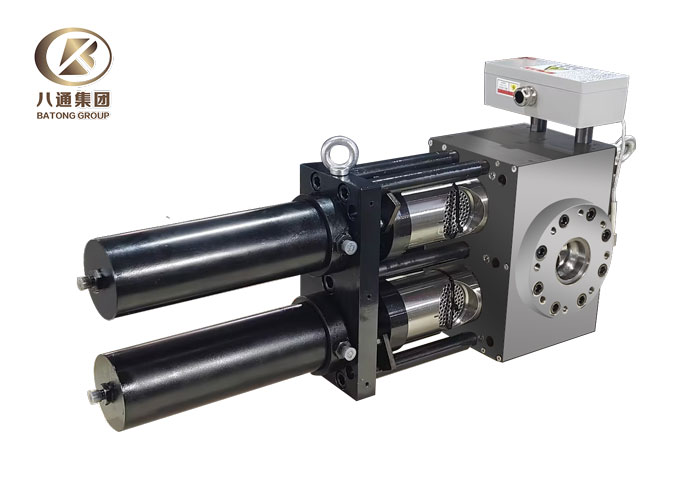

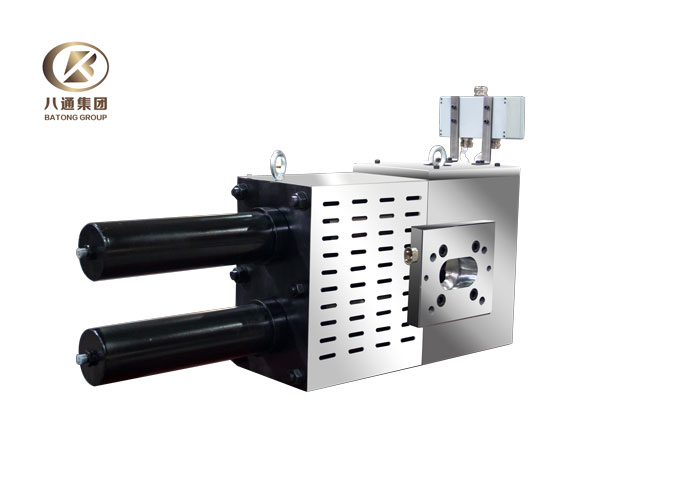

The Double Piston Screen Changer, engineered by Zhengzhou Batong Intelligent, represents a premium filtration solution tailored for high-demand, continuous polymer processing lines. Featuring an innovative dual-piston alternating design, it completely resolves the industry challenge of mandatory production stoppages or pressure/flow fluctuations associated with traditional screen changing. It is the core equipment to achieve the ideal state of “zero downtime, zero interruption” production.

Core Working Principle

The unit is equipped with two independently operating piston cylinders, each capable of holding 1 or 2 filter screen packs. Its secret lies in the “one in operation, one on standby, seamless switching” mechanism. While one piston is engaged in the melt stream performing high-pressure filtration, the other remains in the pre-load position. When the active screen pack becomes clogged, the hydraulic drive system activates, smoothly pushing the standby piston (loaded with clean screens) into the flow path while retracting the clogged one. Throughout this entire process, the melt flow remains entirely uninterrupted, with zero fluctuation in system pressure or temperature, making it exceptionally suitable for precision processing where工艺 stability is paramount.

Key Advantages & Value

True Continuous Production: Unique melt introduction and exhaust design ensure 100% uninterrupted melt flow during screen changeover, maximizing equipment utilization and output.

Ultimate Process Stability: The screen change requires no reduction in extruder backpressure or machine stoppage, completely eliminating pressure spikes and temperature variations caused by the changeover, guaranteeing consistent product quality.

Enhanced Plasticization: Compared to plate-type screen changers, its longer melt flow channel is beneficial for further homogenization and plasticization of the material, improving the performance of the final product.

High Efficiency & Durability: Constructed from nitrided alloy steel, it boasts a robust structure resistant to high temperature, pressure, and corrosion, designed for long-term, high-load operation.

High Automation & Flexibility: Automated operation reduces manual labor and potential errors; modular design facilitates easy maintenance. It is widely applicable for processing various materials, including PP, PE, PET, PA, and rubber.

Technical Overview

Filtration Capacity: Up to 1800 kg/h

Working Pressure: Up to 25 MPa

Screen Size: Up to φ1200 mm

Standard Delivery: 25-30 days

Typical Applications

This equipment is the ideal choice for the following demanding production lines:

High-End Pelletizing: Engineering plastics, PET, and PA for high-quality strand or underwater pelletizing.

Precision Film: BOPP, CPP, HDPE for optical-grade or high-strength film production.

Sheet & Plate: PP, ABS, PC for high-quality thick sheet and plate extrusion.

Fiber & Nonwovens: Meltblown and spunbond non-woven fabric production.

Pipe & Profile: Pipe extrusion with stringent requirements on inner/outer wall smoothness.

Plastic Recycling: Efficiently filtering impurities from complex recyclate materials.

Choosing the Double Piston Screen Changer means investing not just in a piece of equipment, but in superior stability, top-tier efficiency, and future-proof production capability. Backed by Zhengzhou Batong Intelligent's professional manufacturing and reliable service, we empower you to build a flawless, continuous production line.