The

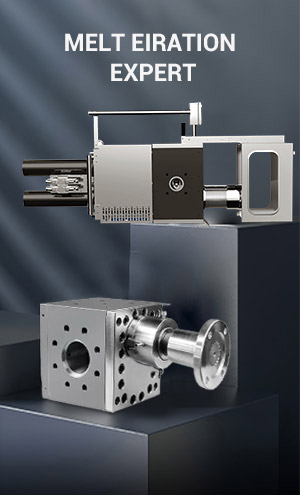

Single Plate Screen Changer, also known as

Manual Slide Plate Screen Changer, is a classic model. It is designed to provide affordable, efficient, and reliable filtration. This is specifically for small to medium-sized extrusion lines. It employs a market-proven sliding plate mechanism, delivering essential filtration through a simple yet robust mechanical design. It is the ideal choice for ensuring melt purity and production continuity in applications such as plastic recycling & pelletizing, small to medium film blowing, sheet extrusion, pipe production, and laboratory-scale extrusion.

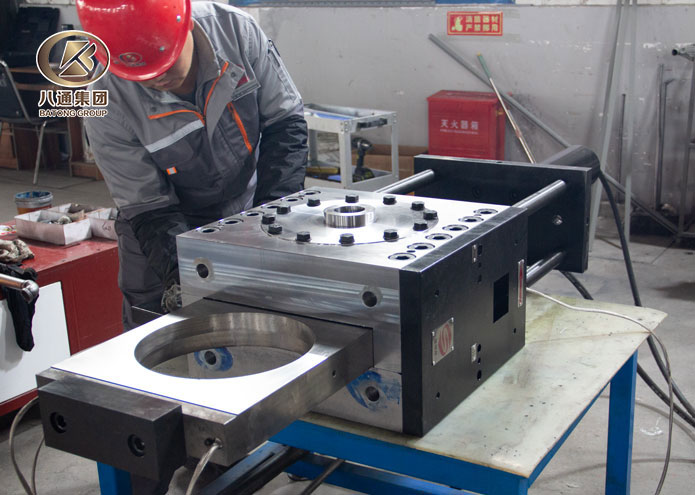

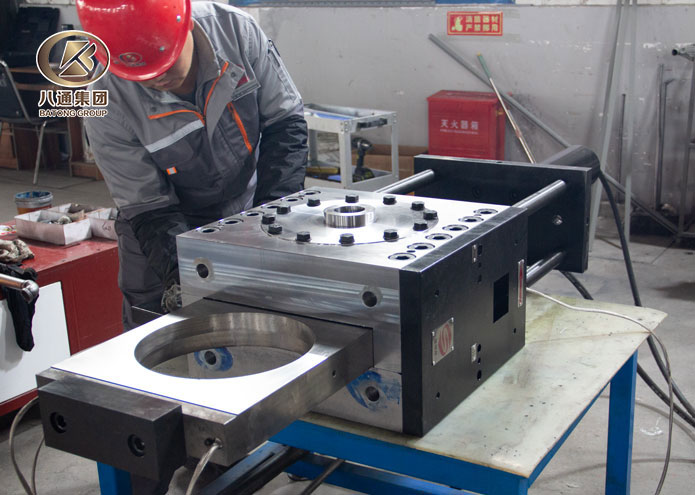

The heart of the device is a precision-machined, high-strength slide plate that holds a pack of filter screens with various mesh combinations. When the screen pack gets clogged in the working position, it raises the system backpressure. The operator can easily slide the plate out. They can use a simple hydraulic pump or a manual lever to do this. The clogged screen pack is taken out for cleaning or replacement. At the same time, a clean screen pack is pushed into place on the other side of the plate. The entire changeover is completed within seconds, resulting in a very brief interruption of melt flow, which effectively maintains process stability.

Batong Intelligent Screen Changer offer three series: square, round, and two-piece types. The main body is made of 45# carbon steel through forging, tempering, and nitriding treatment, with a hardness of 850HV–1000HV and a maximum pressure resistance of 60MPa, suitable for complex working conditions such as high viscosity and high temperature. Its core advantages include non-stop production, fast screen changing, high-efficiency filtration, and easy maintenance. Widely used in extrusion production lines such as granulation, film, sheet, packing tape, and hollow products, it can process various polymer materials like PP, PE, PET, and ABS, effectively improving production efficiency and product qualification rate.